Grinding Rolls

What are Grinding Rolls?

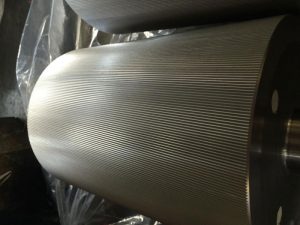

Grinding rolls are cylindrical rollers that are used in roller mills to crush materials such as grains and ores.

Manufacturing Processes

To manufacture these grinding rolls, the following processes were needed:

Centrifugal chill casting – A permanent mould is rotated at high speeds while the molten iron enters the mould. This forces the iron to solidify against the mould walls with superior mechanical properties suitable for this application.

Machining – The shaft ends are machined and key ways cut to tight tolerances to ensure a proper fit in the roller mill.

Groove Cutting – The grooves on the roll surface are cut to the correct specifications of Rotation, Depth, and TPI (Teeth per Inch).

Balancing – The rolls then need to be balanced to ensure smooth, vibration-free operation.

Rust-proofing – In order to withstand the ocean journey, appropriate rust-proofing must be applied. The “industry standard” is to use a thick grease, however, this was forcing our customer to spend hours for clean up. We instead researched and found an alternative product; this food-grade spray we used provided the same protection, but was much easier to clean. Once sprayed, the rolls are carefully wrapped.

Where they are used

These grinding rolls are used for malt mills in the craft brewing and distilling industries. These will grind up the grain into a fine powder that is used in the production of craft beer.